1850-1946 Early industrial history

The first beginnings

“At the end of the 1800’s, Norway was seen as a land of opportunity: rich in water power and with unexploited mineral reserves. This was why foreign investors and international capital were so keen on the resources at Rana.” These are the words of Hilde Gunn Slottemo in her book “Ore, power and people. The history of Rana 1890 – 2005.”

And Rana had a wealth of resources. Abundant deposits of pyrite and chalcopyrite, zincblende, iron ore and silver-bearing galena had been discovered. The rich pickings in the mountains of Rana had been known as early as the 17th century. Experimental silver mining, at Bertelberget and at Nasagruvet, just over the Swedish border, testifies to this.

In 1803, Hans Nielsen Hauge journeyed through Rana. This legendary preacher was also an enterprising businessman, and he foresaw great economic potential in the district:

“In North Rana I also learnt of an iron ore mine and, not long distant, a convenient waterfall and a considerable forest of many miles’ extent. Here, it would seem, an ironworks could in time be established.” 150 years were to elapse before this prophecy was fulfilled.

Båsmoen Mine

Ore prospecting and ore extraction transformed the tiny out-of-the-way settlement of Rana for ever. Industrialisation at Rana really started with ore extraction, when Consul Nils Persson and Engineer Alfred Hasselbom acquired the rights and started industrial mining activity at Båsmoen in 1892.

Under changing owners, exploitation of the Båsmoen Mine continued right up to 1937. The main product was pyrite, and these ore beds were poor in copper, which is often found in conjunction with pyrite.

The first mining operation on Mofjellet mountain started about the same time as Båsmoen, and proceeded spasmodically until more continuous work began in 1926. Mining operations at Mofjellet continued right up to 1986.

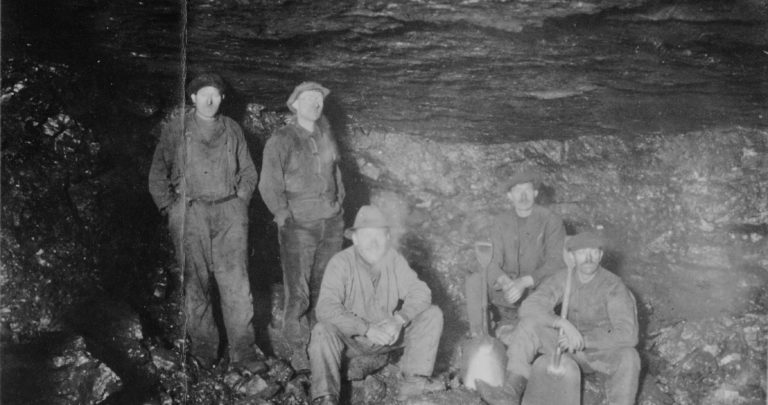

Mine workers in Båsmoen Mine

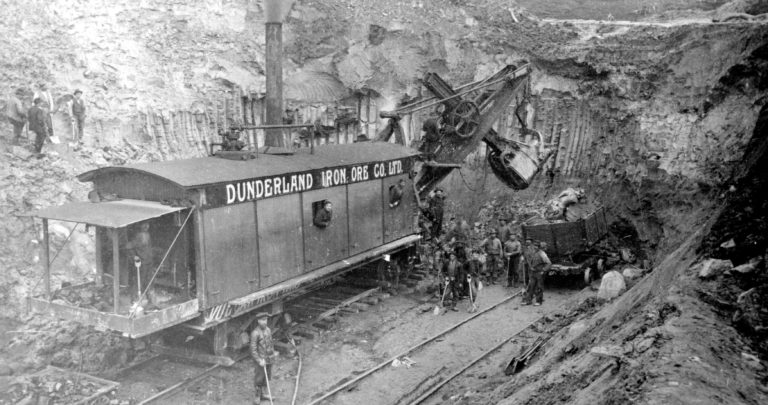

Dunderland Iron Works

The event which caused the big change at Rana was the establishment of the Dunderland Iron Works. In 1899, Consul Nils Persson and Engineer Alfred Hasselbom sold all rights, buildings and equipment relating to the iron ore deposits near Storforshei to the Edison Syndicate for the dizzying sum of 182,000 pounds sterling. In 1902, construction works began, with a factory at Gullsmedvik, a railway to Storforshei and a crusher and other plant at Storforshei. Construction continued until 1906 when the Dunderland Iron Ore Company (DIOC) started operation.

Plant and operation

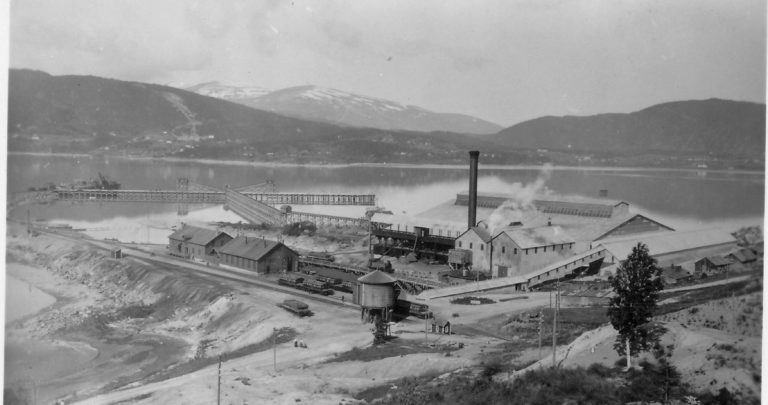

DIOC built the railway from Vika to Storforshei. At Storforshei, buildings were constructed for a crusher and magnetic separator, a power station and an ore concentrate plant. Vika was the location of a briquette production plant, a harbour and a second, identical power station.

The power station was coal-fired and created steam which in turn drove the generators to produce the electricity. The Dunderland Works was a pioneer in iron ore dressing, as production was fully electrified. A number of new patents based on electric motors were applied here in full scale. The technology was the brainchild of Thomas Edison, and became the foundation for a major industry in Rana only 20 years after the world’s first electricity grid was taken into use. In the industrial history of Rana, this side of the Dunderland Works has received little attention.

Production at the Dunderland Vika plant began in 1906, and the first

consignment of iron ore briquettes was shipped to Great Britain on the SS Itune.

But by 1908, all production had stopped, mainly because of serious production problems in the extraction of iron concentrate (haematite) from the ore and the separation of the phosphate mineral apatite. There were also big environmental problems relating to dry separation. At Storforshei, the works were enveloped in dust plumes.

The technology was new and the problems with the Rana ore were just too great. The Dunderland Works was a failure. There were several short operating periods later on, the last continuing until the outbreak of war in 1939.

Briquette production

The intention was to ship the iron concentrate from the Dunderland Works to Britain in the form of briquettes. These were produced at the briquette factory in Vika. Briquettes were the first form of agglomeration used in iron and steel production. At a later date, sinter and pellets were developed, and today briquettes are no longer produced. Even so, this was an important step in the development of the steel industry.

Sydvaranger municipality was developed with mining communities in Kirkenes and Bjørnevatn just after the Dunderland Works. Construction started in 1906, the year that the Dunderland Works was ready for operation. Here too, the construction period lasted four years, and 1910 saw the start of a successful mining operation. Sydvaranger Mine had the advantage that the ore consisted mainly of magnetite.

The owners of Sydvaranger were mainly German investors, together with a number of Norwegians. They chose different patents from Edison’s, and, just like the Dunderland Works, used modern construction machinery during development, and modern mechanised and electrified industrial production when operations started.

A briquette plant was also constructed at Sydvaranger. This was extended and modernised several times, and remained in operation right up to the outbreak of war in 1940. During the 20’s, a sinter works was constructed, but this failed and was pulled down a few years later.

However, the dream of exploiting the abundant iron ore at Rana was crushed only two years after start-up, when operations at DIOC were halted. The patent for extracting iron ore at Rana, developed by genius Thomas Edison, proved unable to create reliable operating conditions. Up to 1916, production fell to minimal levels. There then followed three short operating periods up to 1939.

Sources about the early history of Rana

– Ore, power and people: the history of Rana 1890-2005. “Hilde Gunn Slottemo”. 2007 (in Norwegian)

– A hidden success? “MIP-Info”. Yellow Pages article about Dunderland Works, 2012 (in Norwegian)